CARBON CERAMIC BRAKE PADS

THE ULTIMATE IN SAFETY

Engineered with the highest safety standards,providing optimal braking experience in extreme

driving conditions, HengHua Carbon Ceramic Brake Pads are the best choice for any challenging application.

Our brake pads are designed with the latest braking technology, providing optimal control and shorter

stopping distances, meeting the toughest industry leading safety requirements.

For the ultimate braking experience, HengHua Carbon Ceramic Brake Pads have what it takes

to deliver top-of-the-line stopping power for the serious driver, our unsurpassed brake pads are

the perfect choice to keep your braking system running in peak performance, in every kinds of

driving condition.

CARBON CERAMIC BRAKE PADS

.40,000 to 50,000 km lifetime

.100% asbestos free formula

.Exclusive anti-squeal lubricant

.Smooth pedal feel

.Superior and reliable braking performance

.Exceptionally long lasting pad life

.Maximum noise reduction

.Heavy-duty and reduced disc wear

.Optimum control and shorter stopping distance

.Outstanding fade resistance

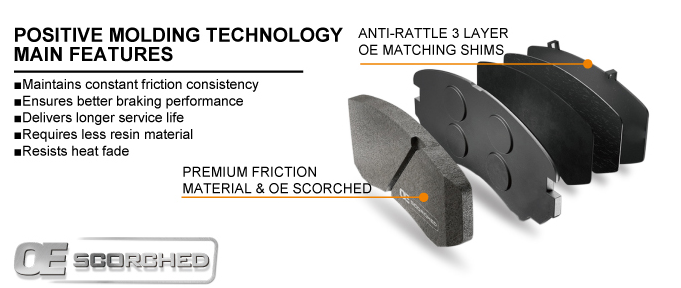

POSITIVE MOLDING TECHNOLOGY

Positive Molding Technology is an important factor in production of our products. Positive molding results in

a more uniform density in the production of the brake pad. It also allows using less resin content in formulation of the

brake pad which can lead to improvement in the fading characteristic of the brake pads. The brake pads produced

by positive molding process is proven to have much better stopping performance. High resin increases fading, which can

increase stop distance up to 50%. All of our brake pads are manufactured using the same positivemolding process utilized

by Original Equipment. Positive molding uses extreme pressure to compress the friction material and bondit to the backing

plate. This process assures consistent friction material density throughout the pad, resulting in even wear and performance

characteristics throughout the life of the brake pad.

OE SCORCHED

In addition to these features, we have added a schorching process to all of our brake pads. This additional

process forces any impurities out of the friction material and pre-burnishes the pads to greatly accelerate

the brake-in process. This OEM process enhances key frictionperformance levels. Scorching raises initial cold

effectiveness, stabilizes friction levels out of the box, providesconsistent performance across the entire operating

range. During the scorching phase, each brake pad surface is super-heated to simulate the initial break-in process

performed by installation technicians.

PACKING:

Plastic film +neutral or OEM or DUORINA box+ neutral or OEM or DUORINA carton +pallet.